麻豆影视在线观看榮(róng)膺美國權威雜誌(zhì)《製造技(jì)術洞察》評選的 “2024 年度亞太地區先進材料解決方案提供商”

近日,常州麻豆影视在线观看新材料科技有限公司憑(píng)借在提高能源效率領域的重大創新成就 ——“Elevating Energy Efficiency Quantum Leap”,被美國(guó)權威雜誌《製造技術洞察(chá)》評選為 “2024 年度亞太地區先進材料解決方案(àn)提供商”。

《Manufacturing Technology Insights》雜誌作(zuò)為全(quán)球製(zhì)造業技術領域的權威刊物(wù),每年都會評選出在(zài)材料科學、製造工藝等方麵有傑出貢獻的企業或個人。2021年全球玻璃纖維製造商中國企業巨石集團和日本著名的跨國公司Tosoh Corporation也曾入選這一(yī)獎項。常(cháng)州麻豆影视在线观看(下文簡稱麻豆影视在线观看)獲得這一殊榮(róng),彰顯了其在(zài)行業內(nèi)的領先地位,進一步鞏固了在亞太區域乃至全球的(de)影響(xiǎng)力(lì)。

優(yōu)納此次(cì)獲獎,得益於在開發和工(gōng)業化生產介孔絕(jué)熱材料方麵的成就。雜誌原文評價“In the quest to curb global energy consumption and its consequential carbon emissions, mesoporous materials have been pivotal. These cutting-edge materials,engineered with finely tuned pore structures, represent a quantum leap in energy efficiency technology. At the forefront of this transformative technology is UniNano Advanced Materials,an enterprise specializing in industrializing mesoporous thermal insulation materials. Harnessing their unique properties, UniNano is setting new standards in sustainable practices with significant improvements in heat retention and energy savings.(在遏製全球能源消耗以及隨之而來的碳排放的(de)過程中(zhōng),介(jiè)孔材料一直發揮著關鍵作用,這些具有精細調整的孔結構設計(jì)的前沿材(cái)料,代表著能源效(xiào)率技術的(de)巨大飛躍。處於這項變革性技術(shù)前(qián)沿的是UniNano Advanced Materials,這是一家專門從事介孔絕熱材料工(gōng)業(yè)化的企業。利用介孔絕熱材料獨(dú)特的(de)特性,麻豆影视在线观看正在為可持續實踐設(shè)定新標準,顯著提高保溫和節能(néng)效果)”。

麻豆影视在线观看專注於將介孔材料的獨特性能應用於熱絕(jué)緣領域,通過優(yōu)化孔隙結構與多種纖(xiān)維的結合,顯著提高絕熱性能。相比傳統纖維基材料如岩棉、矽酸鋁和玻(bō)璃棉等,在投資基本持平的情況下,實現了降低30%以上的散熱損(sǔn)失(shī)。麻豆影视在线观看成功開發了可擴展的製備方法和環保的生產工藝,展現了優異的安全性和環(huán)境友(yǒu)好性,確保介孔(kǒng)材料在熱絕緣領域的大規模應用成為可(kě)能。同時,介(jiè)孔絕熱材料還(hái)具備優異的阻燃性和高疏水性(xìng),並且通過了長達40年的老化測試,具有優異(yì)的耐用性。在成(chéng)本效(xiào)益方麵,雜誌方麵評價道“Compared to advanced materials like nano-aerogels, its mesoporous materials provide similar energy-saving benefits at a lower cost(與納(nà)米氣凝膠(jiāo)等先進材料相比,介孔絕熱材料以更低的成本提(tí)供了類似的節能效果)”。

麻豆影视在线观看的介孔絕熱材料係列產品,已在多個(gè)領域獲得了廣泛應(yīng)用(yòng),包括高溫管道、工業設備和各類設施。其極低的導(dǎo)熱係數、優異的耐火和憎水性能,使其在熱電、化工、鋼鐵製造等多個行業展現出巨大優勢,成功(gōng)實施了超過(guò)500個項目。其中,麻豆影视在线观看為河南能源集團提供的蒸汽(qì)管道隔(gé)熱係統改造方案作為(wéi)經(jīng)典案例受(shòu)到《製造技術洞(dòng)察》雜誌的關注,並(bìng)在報道中對案例進行了詳(xiáng)細描述(shù)。該項目針對長達660米、直徑DN350的蒸(zhēng)汽管道進行了(le)節能改造,通過引入麻豆影视在线观看的先進介孔絕熱材料,成功將隔熱層厚度從250mm縮減至200mm,同時大幅降低(dī)了熱損(sǔn)失和表麵溫(wēn)度,實現了顯著的節能效果。項目完成後(hòu),河南(nán)能源集團每年可節約蒸汽79,200噸(dūn),有效減少了能源消耗和二氧化碳排放。

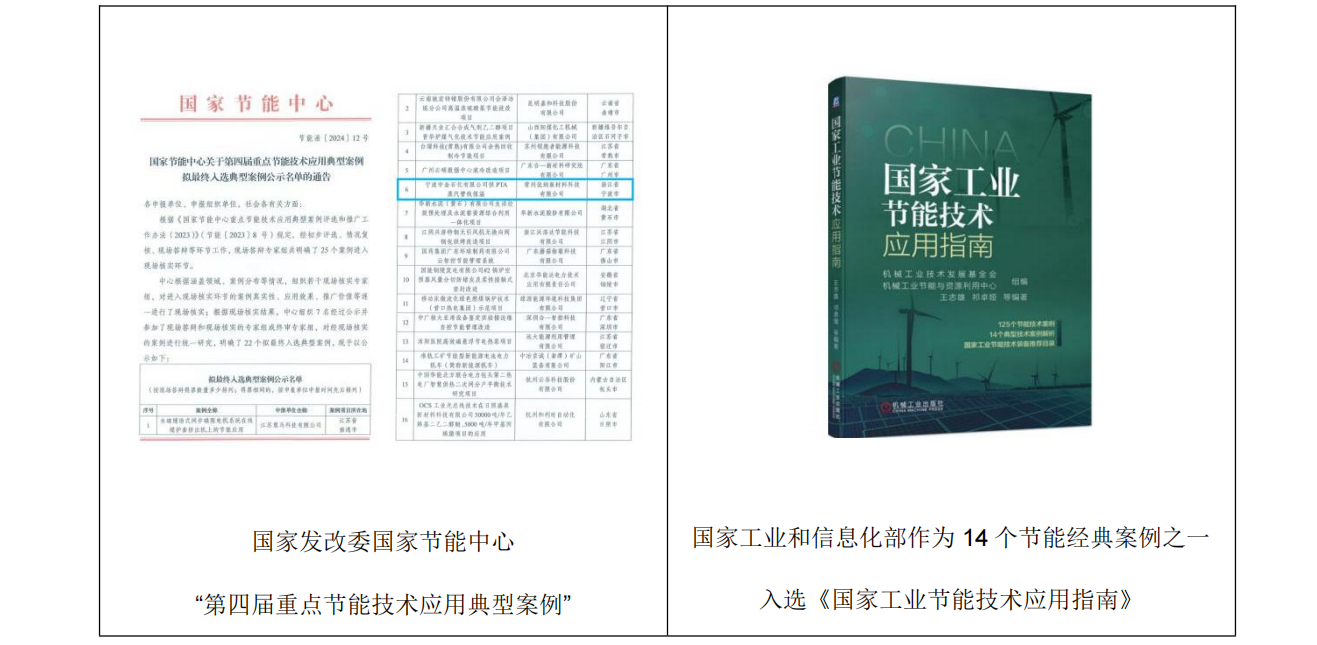

近年來,麻豆影视在线观看在江蘇常州和江西上(shàng)饒都建(jiàn)立了製造工廠,還先後獲“專精特新(xīn)小巨人”、“高新技(jì)術企業”以(yǐ)及“能源科學進步一等獎”等諸多榮譽。分別被國家工(gōng)信部列入《國家工業(yè)和信息(xī)化領域節能降碳(tàn)技術裝備推薦目(mù)錄(2024)》、《國家(jiā)工業節能技術裝備推(tuī)薦目錄(2020)》、被國家發改委國家節能(néng)中心列入重點節能技(jì)術應(yīng)用典型(xíng)案例(lì)、被國家清潔供熱產業列入綠色低碳重大(dà)創新技術(shù),並作為(wéi) 14 個節能經典案例之一,入選《國家工業節能技術應用指南》。同時麻豆影视在线观看還是中國碳中和行動聯盟成員。

自麻豆影视在线观看新(xīn)材誕生之(zhī)初,欒玉(yù)成教授便立足於科(kē)學創新(xīn)的原點,將“以(yǐ)科技振(zhèn)興國家,以實業服務祖國”作為自己(jǐ)的使命,始終堅持不渝(yú)。經過多年的發展,常州(zhōu)麻豆影视在线观看新材不僅構建了穩固(gù)的經營管理基石,還贏(yíng)得了業界的廣泛(fàn)讚譽。在全球可持續發展的驅動下,麻豆影视在线观看將繼續發展新質生產力,並為(wéi)可持續的未來做出積極貢獻。

附《Manufacturing Technology Insights》雜(zá)誌(zhì)報道原文:

In the quest to curb global energy consumption and its consequential carbon emissions,mesoporous materials have been pivotal. These cutting-edge materials, engineered with finely tuned pore structures, represent a quantum leap in energy efficiency technology.

At the forefront of this transformative technology is UniNano Advanced Materials, an enterprise specializing in industrializing mesoporous thermal insulation materials. Harnessing their unique properties, UniNano is setting new standards in sustainable practices with significant improvements in heat retention and energy savings.The company developed and industrialized diverse mesoporous materials with optimized pore structures, combining them with different fibers for enhanced thermal insulation. It achieves more than a 30 percent reduction in heat loss, surpassing traditional fiber-based materials like rock wool, aluminum silicate, and glass wool, which often suffer from inadequate thermal performance, energy efficiency and durability.

UniNano prioritizes cost-effectiveness. Compared to advanced materials like nano-aerogels, its mesoporous materials provide similar energy-saving benefits at a lower cost. It furthered its impact by developing scalable preparation methods, cost-effective production techniques, and environmentally friendly processes to enable large-scale application of mesoporous materials in thermal insulation. Produced using a green, water-based synthesis approach, these flame-retardant materials with low combustion calorific value and high hydrophobicity ensure environmental friendliness and safety across diverse applications. Tested through rigorous, 40-year aging experiments, UniNano’s mesoporous composite insulation materials boast exceptional durability and use about 50 percent less space compared to conventional options.

Delivering outstanding insulation, fire resistance, and waterproofing, its flagship mesoporous insulation series enhances energy efficiency with reduced material usage and extended service life. Engineered for temperatures exceeding 150 °C, these materials find wide application in pipelines, industrial equipment and various facilities, demonstrating success in thermal power, chemical production, steel manufacturing, and other industries with over 500 implementations.

Over the years, UniNano has scripted many success stories, but the transformation at Henan Energy stands out. Faced with an outdated steam pipe insulation system covering 660 meters of piping with a DN 350 diameter and an 11.5-meter-high corridor, Henan Energy initially used 250mm aluminum silicate insulation. This setup resulted in high heat loss (406.9 W/m), a surface temperature of 47.8°C, and a temperature drop of 9.5 to 17°C.

UniNano’s retrofit solution introduced its advanced mesoporous composite material, reducing the insulation thickness to 200mm. This upgrade significantly improved performance: heat loss dropped to 251.7 W/m, surface temperature fell to 39.6°C, and temperature drop was reduced to 5°C.

Dedicated to advancing new materials and refining production processes, the company aims to enhance efficiency, equipment utilization, and overall capacity. It actively engages in industry collaborations and technical exchanges, sharing and absorbing cutting-edge technologies and market insights to foster ongoing innovation.

Through rigorous market research and customer analysis, UniNano develops customized solutions that meet specific industry demands, ensuring its products align closely with customer requirements while promoting sustainability and operational efficiency.

Driven by a commitment to global sustainability, UniNano prioritizes R&D to ensure its industrialization processes are environmentally responsible and contribute to a sustainable future.

(摘(zhāi)自《Manufacturing Technology Insights》(製造技術洞(dòng)察)雜誌(zhì):Uninano Advanced Materials | Top Advanced Materials Solutions Provider In Apac-2024 (manufacturingtechnologyinsights.com))